Recently, Bharat Electronics Limited (BEL) and Safran Electronics & Defense of France have forged a partnership to locally manufacture the HAMMER (Highly Agile Modular Munition Extended Range) smart precision-guided air-to-ground weapon in India. Additionally, Safran Aircraft Engines has expanded its collaboration with Hindustan Aeronautics Limited (HAL) for the LEAP engine programme.

Joint Venture for HAMMER System

The BEL-Safran joint venture focuses on the local production of the HAMMER weapon system, reducing India’s reliance on imports and bolstering the Government of India’s Atmanirbhar Bharat initiative. This collaboration is set to strengthen India’s advanced weapon manufacturing capabilities.

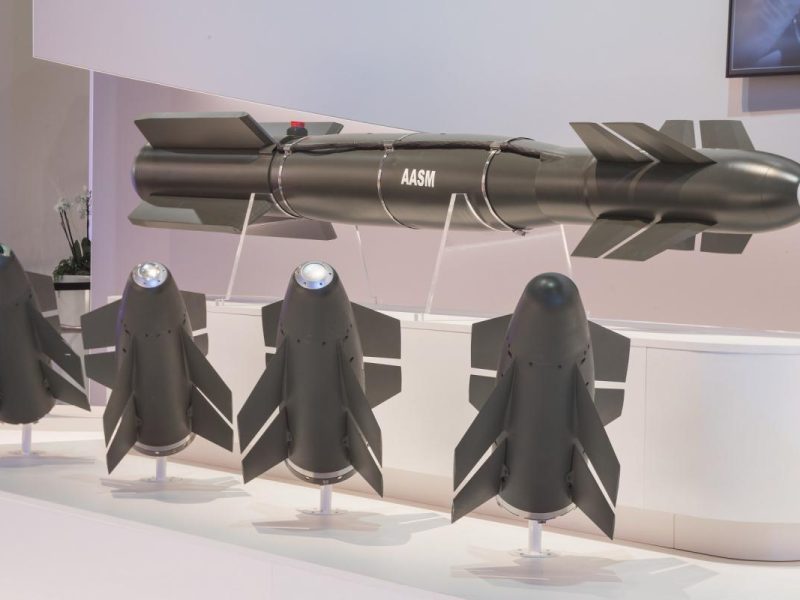

HAMMER Weapon System Overview

The HAMMER is a versatile, high-precision weapon with a modular design that can be deployed across various aircraft, including the Rafale and LCA Tejas fighter jets. It is currently integrated with the Indian Air Force’s Rafale aircraft.

Technology Transfer and Local Manufacturing Opportunities

The BEL-Safran partnership will enable a phased transfer of technology, empowering BEL to take charge of final assembly, testing, and quality assurance. This collaboration also opens up opportunities for small and medium enterprises (SMEs), fostering India’s local manufacturing ecosystem.

Centre of Excellence

A Centre of Excellence will be established as part of the partnership, dedicated to advancing India’s defense capabilities. It will focus on the manufacturing, engineering, and maintenance of optronics and navigation systems, contributing to enhanced military readiness.

HAL-Safran Collaboration for LEAP Engine

During Aero India 2025, HAL entered a long-term agreement with Safran Aircraft Engines to produce critical turbine forged parts for the LEAP engine, strengthening India’s aircraft engine manufacturing sector and advancing self-reliance in aviation technology.

Manufacturing at HAL’s Bengaluru Facility

HAL’s Foundry & Forge Division in Bengaluru will utilize Ring Rolling technology to produce forged components, with a workforce of 400 expected to manufacture 30,000 units annually by 2026.

HAL-Safran’s Previous Successes

The collaboration between HAL and Safran extends beyond the LEAP engine, including the development of the Shakti helicopter engine for the Dhruv and Light Combat Helicopter (LCH), and ongoing work on the Indian Multi-Role Helicopter (IMRH) engine.

India’s Role in LEAP Engine Programme

The LEAP engine, widely used in global commercial aviation, powers 75% of Indian commercial aircraft. Over 370 aircraft in India operate with LEAP engines, and Indian airlines have placed orders for more than 2,000 LEAP engines, cementing India’s pivotal role in the programme.